Lacero: shredding with maximum performance

Story Highlights

- Komptech

- tocator Komptech Lacero

Related Articles

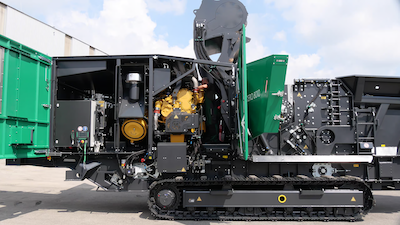

The Lacero high-performance shredder is one of Komptech’s latest innovations. After an intensive development phase, the machine for shredding all types of green waste and wood is now fully established on the market.

The basic idea for the Lacero was to develop a machine with maximum performance in terms of throughput and material quality for the global market. The first presentation and official market launch in Europe took place at IFAT 2022 in Munich. This has now been followed by the official launch on the global market.

The basic idea for the Lacero was to develop a machine with maximum performance in terms of throughput and material quality for the global market. The first presentation and official market launch in Europe took place at IFAT 2022 in Munich. This has now been followed by the official launch on the global market.

The Lacero has been specially designed for demanding tasks and is the ideal solution for customers who expect maximum performance and efficiency when processing large quantities of material. As you would expect from Komptech machines, the Lacero also impresses with its solid and robust construction with a total weight of around 40 tonnes, as well as with the output material quality, which achieves a high degree of fineness. Despite its extreme performance, Lacero remains surprisingly quiet – an important argument, especially in noise-sensitive environments.

In Europe, the Lacero is focused on processing waste wood and green waste. Komptech offers a broad product portfolio that allows different process designs, enabling customers to manufacture a wide range of product qualities. For example, a combination of Lacero and Multistar XXL2 or XL3 can also be used. In the USA, the field of application is strongly focused on mulch processing, without losing sight of the global market.

Technical data

Technical data

The heart of the machine is the massive shredder rotor weighing more than three tonnes in combination with the 800 hp CAT® C18 engine with the latest exhaust gas stage 5, which enables almost any type of green waste and wood to be shredded in a highly efficient manner.

Throughput values of 400 cubic metres per hour in the applications “waste wood treated” and green waste, while at the same time producing a very homogeneous material quality P63 F10 (ÖNORM EN ISO 17225-1), speak for themselves. The huge feed area with active infeed in the form of a steel link conveyor transports the material to the large infeed opening of 760 x 1,520 millimetres. The rotor design has 16 armoured wear plates, enabling it to be used on both sides and thus doubling its service life. The Lacero 8010 is driven by a belt drive, which ensures maximum efficiency. Hydraulic belt tensioning in conjunction with a special clutch ensures optimum power transmission without the need for manual adjustment.

A two-part screen basket system allows the machine to be ideally matched to the desired material quality. The screen basket carrier also has a safety system that triggers on contact with a solid impurity and thus protects the machine from further damage.

The powerful discharge system with a discharge height of almost five meters takes care of material removal. Movement is ensured by a robust tracked undercarriage with a track width of 500 millimeters. The machine is equipped with the Komptech Connect! condition monitoring system as standard. It can be expanded to include fully integrated volume throughput measurement – so you can always keep an eye on your machine.