Volvo Penta reveals its Stage V concept – optimized for tomorrow

Related Articles

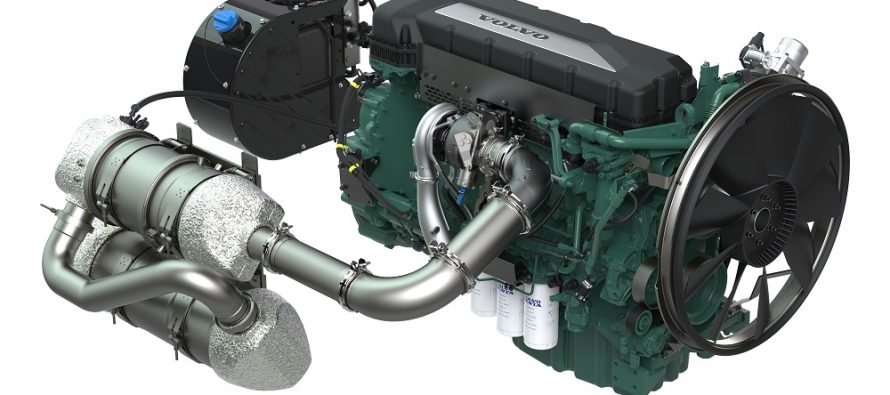

Volvo Penta revealed its Stage V concept at CONEXPO 2017, in early March. As with previous emission steps, the Stage V line-up includes all five engines – D5, D8, D11, D13, and D16 – offering the same power range from 105 to 565 kW (143-770 hp) as Volvo Penta’s existing offer for industrial, off-road applications. A D11 engine and its perfectly matched exhaust aftertreatment system (EATS) were on display to demonstrate the company’s Stage V platform.

Stage V regulations are scheduled to take effect in January 2019, in Europe, requiring new emission limits for diesel and spark-ignited engines used in a variety of industrial applications. The scope of the regulations is set to widen, as for the first time, engines below 19 kW and above 560 kW will be included in the legislation. And while current Stage IV regulations limit the overall mass of particle emissions, Stage V will also affect the number of particles emitted.

Volvo Penta’s new Stage V platform has been optimized to meet the upcoming emission standards, as well as future customer needs. Volvo Penta has taken advantage of proven and mature concepts already existing today across the Volvo Group, and has listened closely to customers to understand their future application requirements. The new Stage V range ensures installation commonality between different emission levels. The engine program will be consistent, from Stage II to Stage V, which is hugely beneficial for OEMs. “We are ensuring compatibility with earlier emissions legislations by using the same hardware layout and re-using the electrical architecture to make sure we have consistency across different emission stages,” said Johan Carlsson, chief technology officer for Volvo Penta. “This means our customers can integrate solutions from across the emission stages at the same time.

For Stage V, the engine has been equipped with a fixed geometry turbo, which contributes to reduced complexity, improved fuel consumption and increased efficiency. A common-rail injection system reduces noise levels and delivers reduced fuel consumption.

Volvo Penta’s Stage V engine and EATS are designed to work together to maximize passive regeneration during normal operation. If needed, the engine-mounted heat management devices will automatically increase the exhaust temperature. The highly efficient selective catalytic reduction (SCR) technology enables the usage of a low complexity engine with robust design. Additionally, the engine concept ensures that it is easy for the EATS to maintain a favorable temperature during normal operation.

With Volvo Penta’s Stage V approach, there is no high temperature regeneration due to the fact that sulfur regeneration in the SCR catalyst is not required; only soot regeneration is needed to clean the diesel particulate filter (DPF).

Displayed at CONEXPO/CON-AGG, the new EU Stage V D11, TAD1180-1182VE, is a powerful, reliable, and efficient six-cylinder engine. With power output ranging from 235-285 kW (320-388 hp), the D11 is designed to deliver maximum power and torque at low rpm. This results in optimized performance, including smooth operation, low noise, and world-class fuel efficiency. The D11 is equipped with all the key features of Volvo Penta’s Stage V concept, such as a common-rail injection system, uncooled EGR, as well as an EPG and inlet throttle.

Volvo Penta offers a flexible EATS, securing ease of installation, operation, and maintenance. A modular approach ensures the EATS can be installed in a number of different configurations and positions.

The EATS includes the following components:

DOC (Diesel Oxidation Catalyst)

DPF (Diesel Particulate Filter)

DEF/AdBlue injection

SCR (Selective Catalytic Reduction)

ASC (Ammonia Slip Catalyst)