Rotar and Lehnhoff combine products and expertise to reach full potential

Related Articles

The demolition industry is in a constant process of growth. Education, health and safety regulations, the increase of more complex projects and more advanced equipment are daily issues demolition companies work with.

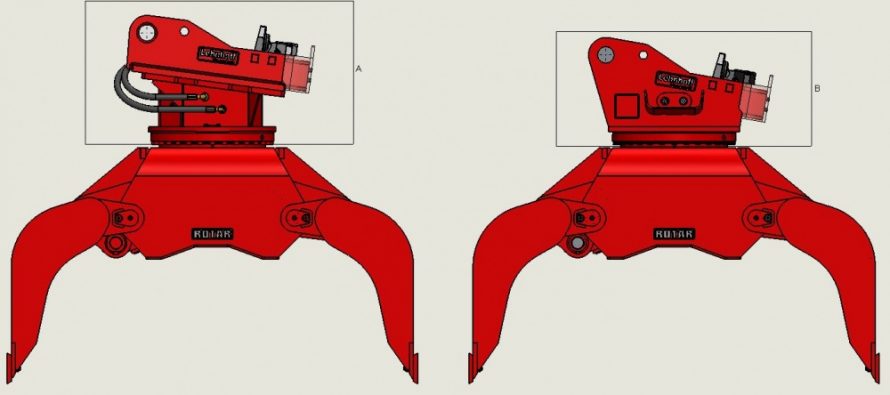

Today’s modern fleet of equipment not always hits all benefits of the full hydraulic quick coupler and the attachment. The combinations do not always reach their full potential. The collaboration between Rotar and Lehnhoff to develop a rotating subhead where the quick-coupler and hydraulic valve block are integrated lets both the attachment and quick coupler reach their full potential. It ensures power, productivity and a more efficient, save and comfortable work environment for the excavator operator.

The collaboration results in the following benefits:

– All hoses and pipes between the attachment and the full hydraulic quick-coupler run inside the subhead and are protected. Hose rupture, oil spills and downtime as a result of the unprotected hoses are things of the past.

– There is no need for a bolt-on adapter with hydraulic valve block as these are integrated, which leads to total weight reduction and a more beneficial point of gravity of the attachment. This revolutionary compact construction method enables excavators to carry stronger and heavier attachments. This results in more productivity and project uptime.

– Rotar and Lehnhoff both focus on an optimal oil flow especially on high oilvolume attachments like shears and pulverizers. In the 100% dedicated attachments, the number of components are reduced and the internal diameter of bores, hoses and pipes are enlarged and in harmony.

– The oil flow is optimal, backpressure is reduced to a minimum, fuel consumption of the excavator is reduced and heat build-up is minimized.

– The lifespan of components is enlarged which results in less malfunctions and higher operational availability.

– No more adapters changing between attachments on the jobsite and unwanted exposure to the dangers a jobsite brings. No more problems with stucked screws or threads and improved uptime.

With this innovative approach, Rotar and Lehnhoff are shortlisted for the 2016 World Demolition Awards in the category “Manufacturers’ Innovation Award: Tools & Attachments”.